Donetsk National Technical University

Mechanical Faculty

Àbstract

of ìaster degree work:

TECHNOLOGICAL BASES OF IMPROVEMENT OF TREATMENT OF WARES FROM FRAGILE NON-METAL MATERIALS

master: Aldokhin À.À.

e-mail: alex-x-x-x-x-x@rambler.ru

leader: acc Baykov À.V.

Urgency of a theme

At processing by the diamond tool on elastic bound lower roughness and depth of a defective layer is , and that reduces labour input of the subsequent processing. At the expense of diamond grains micromovings in elastic bound the structure of the diamond tool is formed which is characterized by a smaller difference of heights between tops of diamond grains. Hence, at cutting processing more grains took part, in comparison with the tool on rigid bound.

The purpose of work

In this connection, the purpose of work is the research of influence of bounds parameters and forces of cutting on size of diamond grain moving. Earlier other authors carried out (spent) works on definition of grain moving under action of normal making force of cutting (tanget a component of cutting force it was not taken into account). Two forces of cutting - normal and tanget work are involved into grain cutting. Therefore important moment is the research of behaviour the grain under action of two making forces of cutting and comparison with results of the previous works.

Method of researches

The most rational way of the decision of intense - deformed condition task is the method of final elements, which is generalization of a direct variational method.

At the decision of the task the model of the grain that was shipped in bound (fig. 1) was used.

Fig. 1. Model of the grain shipped in bound.

The initial data for account are:

- Characteristic of bound material.

- Characteristic of the grain material ( Å = 9·1011Ïà; ì=0,11 ).

- The size and geometry of the grain and bound (the sizes of bound model corresponds to average distance between grains).

- Force of cutting ( Ð y=0.16Í, Ð z=0.05Í )

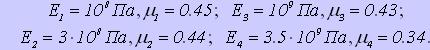

Let's consider four variants of elastic bound, to which the following properties of the material correspond:

Results of work

As a result of the decision the following dependences are received:

- Moving of the grain from the bound characteristic under action only of normal making force of cutting and cumulative action of normal and tangent making forces of cutting (fig. 2);

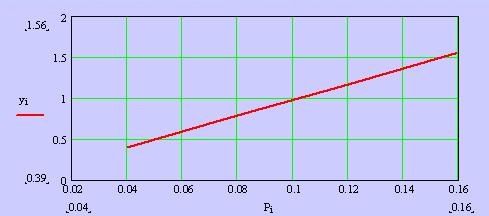

- Moving of the grain from making forces of cutting at the constant characteristic of the bound material (fig. 3).

Fig. 2. Dependence of the grain moving from the bound characteristic under action of only normal making force of cutting and cumulative action of normal and tangent making forces of cutting.

Fig. 3. Dependence of the grain moving from making forces of cutting at the constant characteristic of a material bound.

The analysis showed, that the tangent component of cutting force does not render essential influence on the diamond grain moving: the difference between the grain movings in these cases does not exceed 1 %.

In a fig. 3 the dependence of the grain moving on effort is provided which is linear in character. Within the framework of the given assumptions the linear dependence of moving on effort is caused by elastic (linear) properties of a material bound.

|