|

Navigation on a site

|

Anistratenko Vladimir Leonidovich Faculty : "Computers information's technologies and automation" Speciality: "Electroniń systems" Qualitative parameters pomping out of methane of a complex of the control and automation pomping out of methane The purpose of work - development of recommendations on application of gauges and peripheral devices degass monitoring systems and automatic control, a substantiation of quantitative and qualitative characteristics of parameters pomping out of metane.

Method of research - the analysis of existing means of measurement of parameters of the control, diagnostics, protection and management degass systems and development of recommendations at a choice and development of missing means with specifications allowing to realize a control system with the set functions.

Urgency of a task in view. Now in the coal industry tendencies to reduction of quantity of mines and lavas are observed. At the same time loading on mines and daily extraction from lavas constantly increases. In hi-level lavas, it is especial at improvement much gas layers, the quantity of allocated metane and danger gas the phenomena increases.

Introduction on mines degassing systems will allow to reduce essentially danger gassing displays, to increase safety, loading on mines and to receive economic benefit of recycling extracted metane.

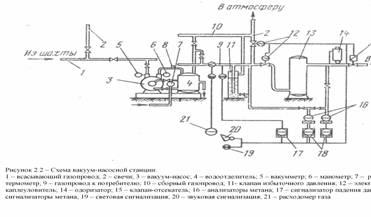

For maintenance of effective and safe work degassing the system consisting from degass of chinks,pomping out gas and delivery pipelines, the vacuum pumps, sucking away fans and other machines, should be equipped with a complex of means of the control, automatic control, diagnostics of a condition of the equipment and protection.

The process equipment should be equipped with the complete set of the instrumentation for the visual control of a condition of system: flowmeters, gas analyzers, manometers, vacuum gauges, thermometers. In this connection, it is necessary to make a choice of necessary devices from the nomenclature which are are released by the industry.

Besides for effective work of a complex of means of the control and automatic control degass systems, it is necessary to choose a line of stationary gauges from existing and to give recommendations on development of missing gauges.

Purpose of work - on the basis of the analysis degass systems as object of automation, and in view of the developed recommendations at the choice of gauges and peripheral devices to create preconditions for the subsequent development of a complex of means of the control, diagnostics and automatic control which will provide:

- The control of aerogas conditions over the locations of the process equipment; - The control cost of chinks; - The control of percentage of metane over chinks and gas mains; - The control of the charge air-metane mix; - The control of temperature of an air-gas mix; - The control of pressure of metane over its compression; - Continuous record in memory of quantity of the extracted metane for change, day, month with an opportunity of reading of the information; - The control and diagnostics of parameters of vacuum - pump stations; - The control and diagnostics of parameters pomping out fans; - Protection and the warning of emergencies in degassing system; - The light and sound warning of the attendants of a pre-emergency; - Distribution of the necessary information on a panel to the operator and the dispatcher on a surface. Degassing system will consist from distributed in space degass chinks, degass pipeline laid on mountain manufactures, a trunk and on a surface of mine, vacuum - pump station on a surface. Chinks join to the degass pipeline. Each chink is equipped with a latch, a water-separator, branch pipes for gauging vacuum, cost of chinks and concentration of metane portable devices and for installation of stationary gauges. Each chink has the limited service life determined maximum permissible minimal cost of a chink and concentration of metane in air-metane mix. The control of work degas systems is carried out stationary, half-stationar and portable devices. The quantity of a taken gas mix, concentration of metane in it, pressure upon an input and an output of vacuum pumps are measured by the stationary devices established on surfaces in vacuum - pump station (VNS). quantity of the extracted metane at decontamination of sites, pressure in gas mains, the maintenance of metane in taken gas are measured half stationar and portable devices. The control over quantity pomping out gas is carried out by recording flowmeters which measuring diaphragms establish in gas mains on the side of a forcing.

|