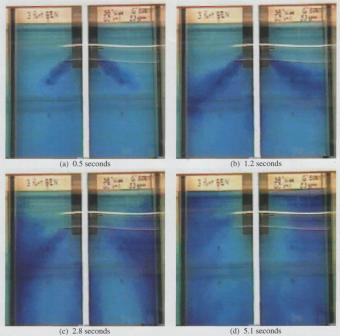

Turbulent flow in the continuous casting process involves transient phenomena and the transport of inclusion particles and plays an important role in the quality of the steel. Liquid flux can also be entrained from the shear of the liquid flow across the top surface and form harmful inclusions. These inclusions and bubbles will either be safely transported to the top surface and removed by the slag layer, or become entrapped in the final product to form costly defects (e.g. internal porosity, blisters, slivers etc.). The flow in the mold region is highly turbulent with Reynolds numbers exceeding 100,000. The chaotic structures of this transient flow greatly influence the unsteady transport of the inclusions and bubbles, which has been evidenced by intermittent defects in plant observation. This project aims at understanding the physics of this chaotic flow and particle behavior, and based on this to develop more accurate and efficient mathematical models for this multiphase flow. Implementation of measuring in caster difficultly and expensive by reason of high working temperature. By reason of that kinematics viscidity of liquid steel and water is practically identical, a stream in caster is studied with the use of the scaled waters models, with which it is easier to work and which allow by sight to represent a stream. Recently we applied measuring of speed of appearance of particles, probably, most exact technique of the dvumernogo measuring of speed of stream, to study a stream in a water model in a scale 0,4. Though and represents the special value, nevertheless, a water model differs from the real pouring on МНЛЗ in a few aspects which are very important for the stream of liquid. At first, lateral walls which represent a locomotive hardening crust do not have pores and stationary. Besides a water model has a flat bottom with the outputs openings in place of cone-shaped bath of liquid metal. These two basic differences result in the different phenomena in a stream, which will be explored. This work represents the results of two designs of stream in the mold, including moving of including and calculation of capture. The our previous of works defined that exact determination of unstationar speeds of stream on exits from the tape-holes of glass, which are terms on the entrance for the designs of the mold, important for the exact calculation of stream in the mold.